50CrVA Spring Steel 50CrV4

Short Description:

Chemical Composition: C(%) Si(%) Mn(%) P(%) S(%) Cr(%) Ni(%) Cu(%) V(%) 0.46~0.54 0.17~0.37 0.50~0.80 ≤0.030 ≤0.030 0.80~1.10 ≤0.35 ≤0.25 0.10 ~ 0.20 Mechanical Propoerties: Yield Strength Rp0.2(MPa) Tensile Strength Rm(MPa) Impact Energy KV(J) Elongation A(%) Hardness ≥ 1127(115) ≥ 1274(130) ≥ 98 ≥ 10 ≤ 321HB Heat treatment specification and metallographic structure: Heat treatment specification: hot-rolled steel is delivered in ...

Product Detail

FAQ

Product Tags

Chemical Composition:

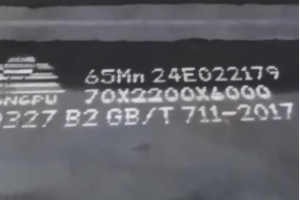

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Cu(%) | V(%) |

|---|---|---|---|---|---|---|---|---|

| 0.46~0.54 | 0.17~0.37 | 0.50~0.80 | ≤0.030 | ≤0.030 | 0.80~1.10 | ≤0.35 | ≤0.25 | 0.10 ~ 0.20 |

Mechanical Propoerties:

| Yield Strength Rp0.2(MPa) |

Tensile Strength Rm(MPa) |

Impact Energy KV(J) |

Elongation A(%) |

Hardness |

|---|---|---|---|---|

| ≥ 1127(115) | ≥ 1274(130) | ≥ 98 | ≥ 10 | ≤ 321HB |

Heat treatment specification and metallographic structure:

Heat treatment specification:

hot-rolled steel is delivered in heat-treated or non-heat-treated state, and cold-drawn steel is delivered in annealed state.

Metallographic structure:

quenched at 850℃±20℃, oil-cooled; tempered at 500℃±50℃ (for special needs, ±30℃), the organization is tempered troostite or a mixed organization of troostite and sorbite.

Critical point temperature (approximate value) Ac1=752℃, Ac3=788℃, Ar3=746℃, Ar1=688℃.

Quenching and tempering treatment specification:

quenching temperature 860-880℃, oil cooling; tempering temperature 500±10℃, water and oil cooling.

Equivalent Grade:

American : G61500

Japanese : SUP10

German : 50CrV4

British : 735A51

French : 50CrV4

FAQ Content

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)