40Cr

Short Description:

40Cr steel is an alloy structural steel. 40Cr alloy structural steel conforms to GB/T 3077 steel, and its quenched and tempered hardness is between 38~45HRc. Delivery hardening less than 250HB after annealing. The mechanical properties of 40Cr are very similar to 35CrMo. But the price of 40Cr is lower than 35CrMo4, which is more economical for users. What is the chemical composition of 40Cr steel? The chemical elements of 40Cr steel are as follows: Carbon C:0.37-0.44 Silicon Si:0.17-0.37 Mang...

Product Detail

FAQ

Product Tags

40Cr steel is an alloy structural steel. 40Cr alloy structural steel conforms to GB/T 3077 steel, and its quenched and tempered hardness is between 38~45HRc. Delivery hardening less than 250HB after annealing. The mechanical properties of 40Cr are very similar to 35CrMo. But the price of 40Cr is lower than 35CrMo4, which is more economical for users.

What is the chemical composition of 40Cr steel?

The chemical elements of 40Cr steel are as follows:

Carbon C:0.37-0.44

Silicon Si:0.17-0.37

Manganese Mn:0.50-0.80

Sulfur S:≤0.015

Phosphorus P:≤0.025

Chromium Cr: 0.80-1.10

After quenching and tempering treatment, GB 40CR alloy steel is a high-quality quenched and tempered alloy structural steel, which belongs to high-quality low-carbon, low-alloy chromium, molybdenum, nickel surface-hardened steel with good comprehensive mechanical properties and good low-temperature impact toughness.

Mechanical properties of 40Cr steel

The typical mechanical properties of 40Cr steel include the hardness of steel plate and steel coil as hot rolled, the hardness after annealing, the hardness of different cooling media

Quenching hardness under quality, etc., the specific parameters are as follows:

Hot rolling hardness: ≦300

Annealing hardness: ≦180

Water quenching temperature: 800-880°C

Water quenching hardness: ≧47HRC

Oil quenching temperature: 800-890°C

Oil Quenching Hardness: ≧45HRC

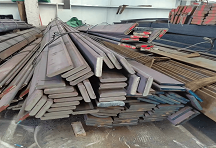

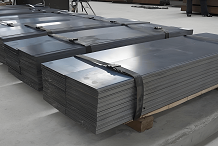

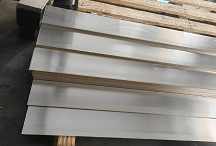

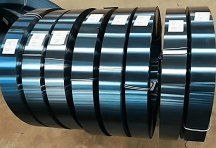

Forms of 40Cr steel

40Cr steel can be made into round bars, round bars, flat bars, plates, hexagonal bars, and cubes. The above forms can be processed into specific sizes according to your needs.

Hardness of 40Cr

The hardness of 40Cr after quenching and tempering is in the range of 32-36HRC, which is about 301-340HB.

FAQ Content

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)