Mat.No. 1.0460، DIN C22.8، ايسي 1022M

وصف قصير:

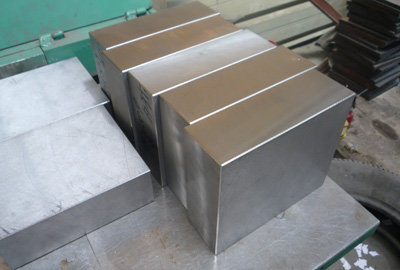

Designation by Standards Mat. No. DIN EN AISI 1.0460 C22.8 - 1022M Chemical Composition (in weight %) C Si Mn Cr Mo Ni V W Others 0.21 max. 0.40 0.65 max. 0.30 - - - - Al=0.033 Description C22.8 is one of the very commonly used plain carbon steels. It has a nominal carbon content of 0.22% with approximately 0.65% manganese. It is a good combination of strength and ductility and may be hardened or carburized. Applications C22.8 steel is typica...

تفاصيل المنتج

التعليمات

علامات المنتج

تسمية المعايير

| حصيرة. لا. | DIN | EN | ايسي |

| 1.0460 | C22.8 | - | 1022M |

التركيب الكيميائي (وزن٪)

| C | سي | مليون | كر | مو | ني | الخامس | W | الآخرين |

| 0.21 | كحد أقصى. 0.40 | 0.65 | كحد أقصى. 0.30 | - | - | - | - | آل = 0.033 |

وصف C22.8 is one of the very commonly used plain carbon steels. It has a nominal carbon content of 0.22% with approximately 0.65% manganese. It is a good combination of strength and ductility and may be hardened or carburized. تطبيقات C22.8 steel is typically used for moderate strength structural applications such as cold formed fasteners and bolts. It is often used in the case hardened condition. الخصائص الفيزيائية (قيم أفاراجي) في درجة حرارة الجو المحيط Modulus of elasticity [103 س N / مم 2]: 210 Density [g/cm3]: 7.84 لينة التليين Heat to 870-980س C, cool slowly. This will produce a minimum tensile strength of 450 MPa. تخفيف الاجهاد Stress relieving to remove machining stresses should be carried out by heating to approx. 540س C, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment. تصلب Harden from a temperature of 820-870س C followed by water quenching. هدأ Tempering temperature: Please ask. تزوير Hot forming temperature: 1050-850س C.التشغيل في الماكينات Machinability is good at 65% compared to 1112 carbon steel as 100% baseline. المقاومة للتآكل Not corrosion resistant. The steel will rust unless protected. لحام Readily weldable by all of the standard methods. العمل الباردة C22.8 steel is readily cold worked by all conventional methods. A stress relief anneal may be needed after extensive cold work. تنصل The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

التعليمات المحتوى

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)