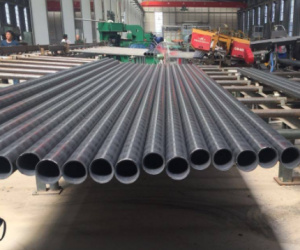

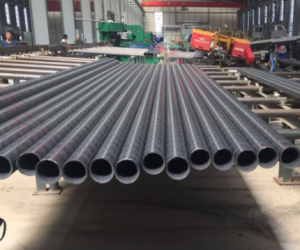

ASTM A335 P92 High pressure boiler pipes

Short Description:

Steel grade: ASTM A335 P92 Packing: Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested. Inspection and Test: Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test. Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, ...

Product Detail

FAQ

Product Tags

Steel grade: ASTM A335 P92

Packing:

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Chemical Requirements of ASTM A335 P92

| UNS Designation | K92460 |

| Carbon | 0.07–0.13 |

| Manganese | 0.30–0.60 |

| Phosphorus(max) | 0.02 |

| Sulfur(max) | 0.01 |

| Silicon | 0.50 max |

| Chromium | 8.50–9.50 |

| Molybdenum | 0.30–0.60 |

| V | 0.15-0.25 |

| N | 0.03-0.07 |

| Ni (max) | 0.4 |

| Al(max) | 0.02 |

| Cb | 0.04-0.09 |

| W | 1.5-2.00 |

| B | 0.001-0.006 |

| Ti (max) | 0.01 |

| Zr(max) | 0.01 |

Mechanical Properties of ASTM A335 P92

| Properties | Data |

| Tensile strength, min, (MPa) | 620 |

| Yield strength, min, (MPa) | 440 |

| Elongation, min, (%), L/T | 20/… |

Material & Manufacture

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

Heat Treatment

- A / N+T

- N+T / Q+T

- N+T

Mechanical Tests Specified

- Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test

- For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested.

- For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe.

FAQ Content

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)